wehewehe

Hōʻike huahana

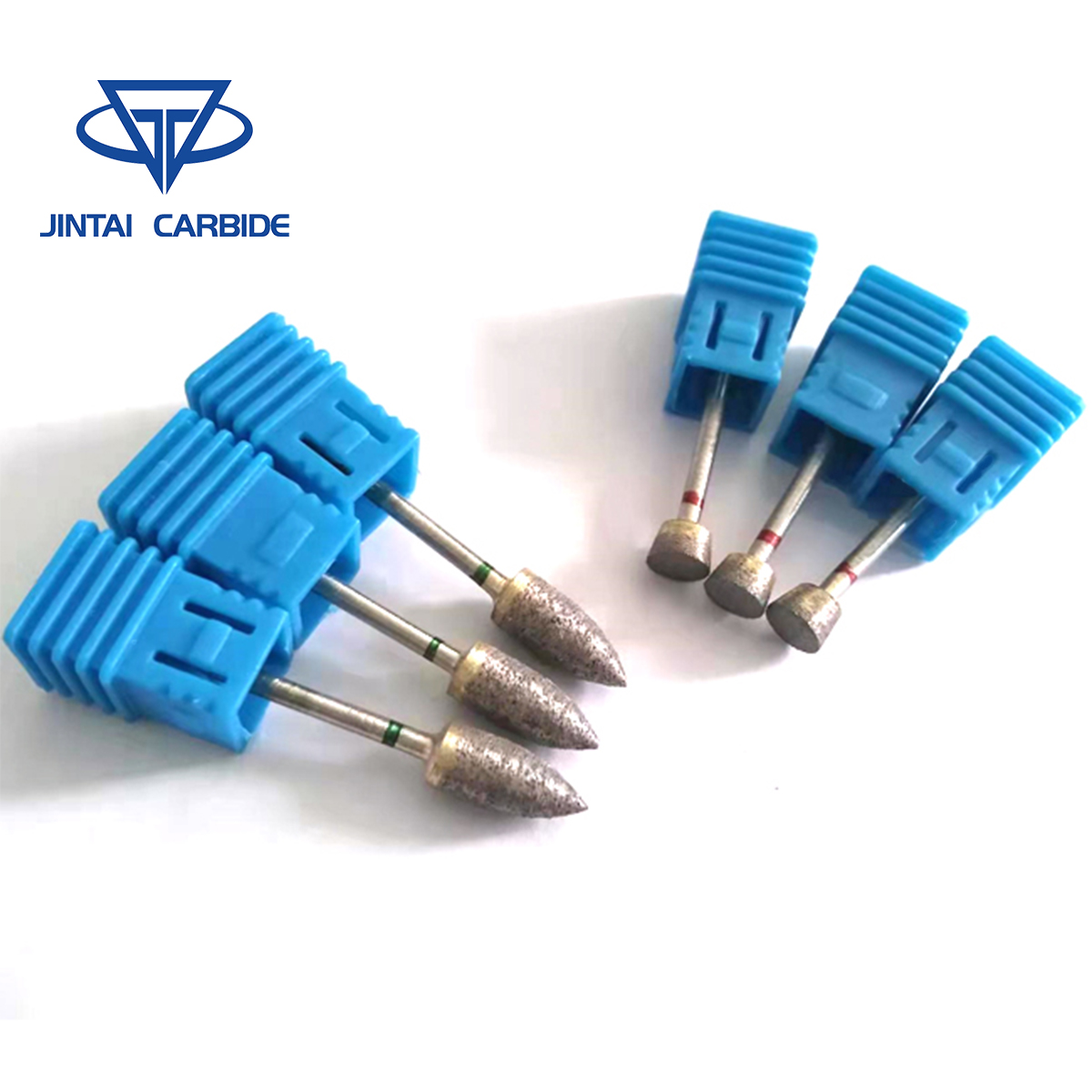

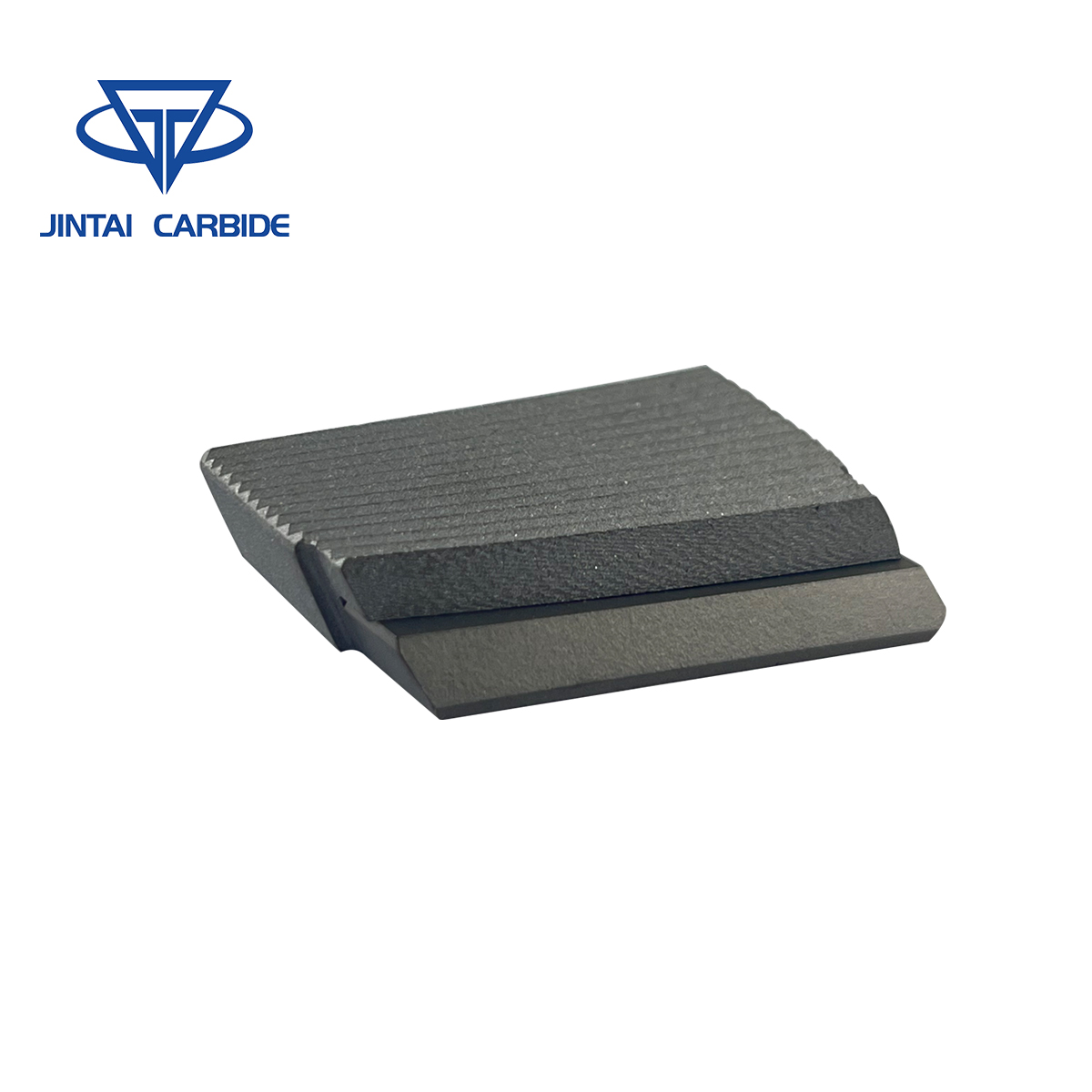

ʻO ke koʻokoʻo carbide i hoʻopaʻa ʻia he pololei maikaʻi, ʻoi aku ka paʻakikī, a me ka paʻa paʻa.

Paipai ʻia nā wili hope, reamers a me nā gravers.Hana maikaʻi no ka ʻoki wikiwiki ʻana.He kūpono no ka ʻoki ʻana i ke kila paʻakikī, ke alumini alumini a me ka alloy Titanium.Hāʻawi mākou i ka hana maʻamau, kokoke i ka ʻupena-ʻano, nā blank insert premium i ka carbide cemented - ʻike ʻia ʻo Tungsten carbide a i ʻole carbide paʻa.

mea haku mele:

1. Nā Pono Kino:

A) ʻoi aku ka paʻakikī ma mua a i ʻole like me 92.8 HRA;

B) ʻOi aku ka nui ma mua a i ʻole like me 14.2 g/cm³;

C) ʻoi aku ka nui o TRS ma mua a i ʻole like me 4200 N/mm²;

D) ʻAʻohe o ke kūlana ETA;

E) ʻAʻohe haumia e nā mea ʻē aʻe;

F) Porosity = A00 / B00 / C00 ;

G) Kaulike ka nui o ka palaoa.ʻAʻole hiki ke ʻoi aku ka nui o ka palaoa ma mua o ka mea i kuhikuhi ʻia.

H) ʻO Chromium carbide ka mea hoʻoulu ulu wale nō.

2.ʻO nā mea hana a pau, hoʻohanaʻia nā pale ma Germany, Switzerland, nā mea hana hana;

3. Ua manaʻo ʻia e ʻoki ʻia ma lalo o 60HRC;

Hiʻona

1. 100% puʻupaʻa maka mea.

2. Loaʻa nā ʻano helu like ʻole ma muli o ke noi a ka mea kūʻai aku.

3. loaʻa iā mākou ka laina hana kiʻekiʻe kiʻekiʻe a me nā lako inspection e hōʻoia i nā huahana kiʻekiʻe.

4. ʻO ka Ground pololei a me ke kaʻina hana polishing kiʻekiʻe

5. Kiʻekiʻe ʻaʻahu kūpaʻa, kiʻekiʻe paʻakikī a me ka paʻakikī hopena

6. ʻenehana kiʻekiʻe, wili pololei.

Papa Papa

| Papa | ISO Code | Nā Pono Mechanical Kino (≥) | Palapala noi | ||

| ʻO ka mānoanoa g/cm3 | Paʻakiki (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | He kūpono no ka hana pololei ʻana i ka hao a me nā metala non-ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | He kūpono no ka mīkini pololei a me ka semi-finishing o ka hao a me nā metala non-ferrous, a me ka hana ʻana i ke kila manganese a me ke kila kinai. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | He kūpono no ka hoʻoheheʻe ʻana a me ka mīkini ʻokiʻoki o ka hao hao a me nā ʻāpana māmā, a hiki ke hoʻohana ʻia no ka mīkini paʻakikī o ka hao a me ke kila kila haʻahaʻa. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | He kūpono no ka hoʻokomo ʻana i nā ʻāpana wili pōhaku rotary impact a me rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | He kūpono no ka hoʻokomo ʻana i nā ʻāpana niho ʻōniʻoniʻo a i ʻole conical no nā mīkini ʻeli pōhaku kaumaha no ka hoʻoponopono ʻana i nā hana pōhaku paʻakikī. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | He kūpono no ka ho'āʻo tensile o nā kaola kila a me nā paipu kila ma lalo o nā lakio hoʻoemi kiʻekiʻe. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | He kūpono no ka hana ʻana i nā dies stamping. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | He kūpono no ka hana ʻana i ke anu anuanu a me ke kaomi anu i make no nā ʻoihana e like me nā ʻāpana maʻamau, nā bearings, nā mea hana, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | He kūpono no ka mīkini pololei a me ka semi-hoʻopau ʻana o ke kila kuhiliʻole a me ke kila kila maʻamau. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | He kūpono no ka semi-hoʻopau ʻana o ke kila kila a me ke kila kila haʻahaʻa. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | He kūpono no ka hana pololei ʻana i nā mea hao, nickel-based kiʻekiʻe-mehana, a me ka ikaika kiʻekiʻe. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | He kūpono no ka ʻoki ʻana i ke kila a me ka hao. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | He kūpono no ka mīkini pololei a me ka semi-finishing o ke kila a me ka hao. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | He kūpono no ka mīkini kikoʻī a me ka semi-finishing o ke kila a me ka hao, me ka helu hānai haʻahaʻa.Hoʻolālā kūikawā ʻia ʻo YS25 no nā hana wili ma ke kila a me ka hao. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | He kūpono no nā mea hana ʻoki kaumaha, e hāʻawi ana i nā hopena maikaʻi loa i ka hoʻohuli ʻino ʻana o nā hoʻoheheʻe ʻana a me nā mea hao kila like ʻole. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | He kūpono no ka hoʻokomo ʻana i nā ʻāpana wili pōhaku rotary impact a me ka wili ʻana i nā ʻano pōhaku paʻakikī. |

Kaʻina Kauoha

Kaʻina Hana Hana

Hoʻopili ʻia

-

ʻO Tungsten Carbide Rotary Burr A i ʻole Die Grinder Bits

-

ʻO Tungsten Carbide Mea Hana Laau a me STB

-

Tungsten Carbide Scalping Cutter No ke keleawe a me ...

-

Tungsten Carbide Surface Milling Inserts No Al...

-

Tungsten Carbide ISO maʻamau Brazed ʻōlelo aʻoaʻo

-

ʻO Tungsten Carbide Fiber Optic Cleaver Hoʻololi ...